Picture a commercial property without any indoor applications—imagine how bare it would feel without the use of stranded wires. Stranded wires are composed of multiple thin strands, typically made of copper, which are twisted and bundled together within a PVC jacket, forming a multi-strand conductor. Their versatility allows them to adapt to various needs, and they come in numerous forms. Below, we’ll explore some of the most common types of stranded wires.

Types of Stranded Wires

Although the fundamental concept behind stranded wires remains consistent, they differ significantly in design. Here are some of the primary types of stranded conductors, including Class-2 and Class-5 varieties:

- Bunched Strands

In this type, the thin strands are gathered together in a single direction, but they lack a specific geometric arrangement. Tight twisting and bunching enhance flexibility, durability, and resistance. It's worth noting that the individual wires don’t maintain a fixed position within the strand.

- Concentric Strands

A concentric stranding conductor features a central core surrounded by one or more layers of individual wires. The initial layer contains the smallest number of wires, while each subsequent layer increases by six additional wires compared to the previous one. Due to their concentric arrangement, the need for filler materials is minimized.

- Annular Conductors

This type of stranding conductor has a core made entirely or partially of non-conductive material. Insulated wires are stranded in reversed concentric layers around this core. This approach reduces resistance while maintaining the wire’s shape, offering a practical advantage.

- Rope Strands

When multiple wires are grouped into several bundles, these are referred to as rope strands. Each bundle is then arranged in concentric circles to form a cable. These are known for their high durability and flexibility (Class-5 type), making them suitable for applications requiring consistent movement.

- Compact Conductors

A compact stranding (Class-2 type) conductor involves each layer being stranded in the same direction and then rolled into its ideal shape. Afterward, the conductor is compressed to eliminate air gaps between strands, resulting in a smoother, more compact design with a narrower diameter.

As you’ve seen, stranded wires come in many variations, each with its distinct properties and advantages. Therefore, selecting the appropriate stranded wire for your needs is crucial. Keep reading to learn how to make the right choice.

How to Select the Perfect Stranded Wire

Picking the right stranded wire is vital for the success of your project or the seamless operation of your product. Follow these steps to guide your decision-making process:

- Assess the required wire gauge and length.

- Determine the necessary flexibility—whether you need a solid core, coarsely stranded, or finely stranded wire.

- Evaluate the type of insulation best suited for your application.

- Choose wire colors strategically to ensure clarity for your team or end-users.

- Decide whether to use copper or aluminum stranded wire.

With this knowledge in hand, you might now be curious about which brand to trust. Rest assured, we’re here to help!

KEI Industries: India’s Premier Stranded Wire Manufacturer

KEI Industries, originally founded as Krishna Electrical Industries in 1968, initially focused on manufacturing house wiring rubber cables. Recognizing the growing demand for stranded wires due to their numerous benefits, Mr. Anil Gupta, a prominent figure in the industry, seized the opportunity to expand KEI Industries' offerings. Today, the company has evolved from a modest office into a globally recognized brand with over 5,000 channel partners worldwide! For more information about our stranded wires, feel free to reach out via email at [insert email]. If you’d like to explore our other products, such as extra-high voltage cables, low voltage cables, communication or instrumentation cables, fire-resistant cables, or solar cables, visit our website at www.kei-ind.com.

At KEI Industries, we pride ourselves on delivering quality products and exceptional service. Our commitment to innovation and customer satisfaction has made us a trusted name in the industry. Whether you're looking to upgrade your electrical infrastructure or seeking specialized solutions, we’re here to assist you every step of the way. Contact us today to discover how KEI Industries can meet your stranded wire needs and beyond!

Optical Flats mirrors are ideal for a variety of applications including interferometry, imaging systems, laser applications, optical path folding, and autocollimation. These mirrors are available in a variety of coating and substrate options, along with surface flatness options of λ/10 and λ/20. Fused Silica, is optically clear and features excellent resistance to abrasion and high durability, making it the best choice for applications in harsh environments.

The mirrors are available in circular, square, and rectangular dimensions. Rectangular first surface mirrors are ideal for applications requiring the mirror to be mounted at 45° in order to produce a 90° bend in the light path.

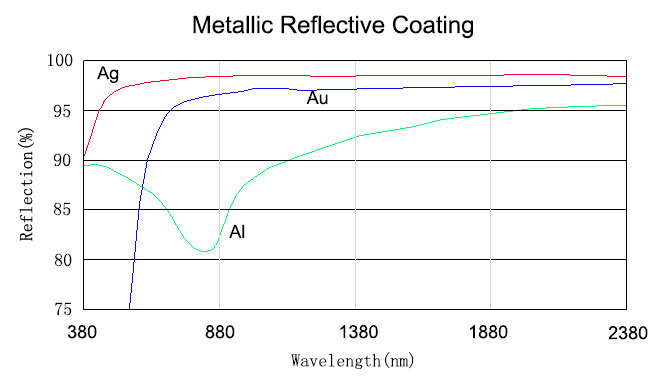

Protected metallic coatings provide a moderate level of reflection over a very broad spectral range and are widely used as mirrors. These coatings are protected by a thin layer of dielectric material in order to make them durable. Enhanced metallic coatings provide greater reflection across the operating band width. These coatings are enhanced by adding a multilayer dielectric stack. Metal coatings will modify the state of polarization of an incident beam of light and are therefore inappropriate for most polarization sensitive applications.

+

Optical Glass Flat Mirror,Optical Glass Protective Flat Mirror,Al Protective Mirror,Aluminium Flat Mirror

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com