Think about a commercial building without any indoor applications—without stranded wires, that’s exactly how things would look. Stranded wires consist of multiple thin strands, usually made of copper, which are twisted and bundled together within a PVC jacket, forming a multi-strand conductor. Their versatility allows them to be used in various configurations, catering to diverse needs. Below, you’ll learn more about the different types of stranded wires.

Types of Stranded Wires

Although the fundamental concept of stranded wires remains consistent, they come in many forms. Here are some of the most common types of stranded conductors, including Class-2 and Class-5 types:

- Bunched Strands

In this type, the thin strands are gathered together in one direction without a specific geometric arrangement. Tight twisting ensures flexibility, durability, and resistance. The individual wires aren’t fixed in place within the strand.

- Concentric Strands

This conductor features a central core encircled by one or more layers of individual wires. The first layer contains the fewest wires, with each subsequent layer having six more than the previous one. The concentric arrangement minimizes the need for filler materials.

- Annular Conductors

In this configuration, a non-conductive core forms the center, which may be fully or partially covered. Insulated wires are stranded in reverse concentric layers around this core, reducing resistance while maintaining shape—a perfect balance for many applications.

- Rope Strands

Multiple wires are grouped into several bundles, which are then arranged in concentric circles to form a cable. Known for their high durability and flexibility (Class-5 Type), these are ideal for situations requiring consistent movement.

- Compact Conductors

Compact stranding (Class-2 Type) involves each layer being twisted in the same direction and then rolled into its final shape. Afterward, they’re compressed to eliminate air gaps between strands, resulting in a smoother, more compact design with a narrower diameter.

As you’ve seen, stranded wires differ significantly in properties and uses. Therefore, selecting the appropriate stranded wire for your needs is crucial. Keep reading to discover how to make the right choice.

How to Select the Perfect Stranded Wire

Picking the right stranded wire is vital for the success of your project or the seamless operation of your product. Follow these steps to guide your decision-making process:

- Decide on the wire gauge and length required.

- Assess the level of flexibility you need—whether solid core, coarse stranding, or fine stranding.

- Consider the type of insulation that best suits your application.

- Choose wire colors carefully to ensure clarity for your team or end users regarding their intended purpose.

- Decide between copper or aluminum stranded wires based on cost, conductivity, and weight considerations.

Now that you understand how to select the correct stranded wire, you might be curious about where to find a reliable supplier. Don’t worry—we’ve got you covered.

KEI Industries – India’s Premier Stranded Wire Manufacturer

Founded in 1968 as Krishna Electrical Industries, KEI Industries initially focused on manufacturing house wiring rubber cables. Recognizing the growing demand for stranded wires due to their numerous advantages, the company seized the opportunity to expand. Over the years, KEI Industries has evolved from a small office to a globally recognized brand with over 5,000 channel partners worldwide! For more information about our stranded wires, feel free to reach out via email at [insert email]. If you’d like to explore other products such as extra-high voltage cables, low voltage cables, communication cables, fire-resistant cables, or solar cables, visit www.kei-ind.com.

We take pride in offering high-quality stranded wires designed to meet modern standards and exceed expectations. Whether you’re working on industrial projects or consumer electronics, our range of products ensures reliability and performance. Contact us today to experience the KEI difference!

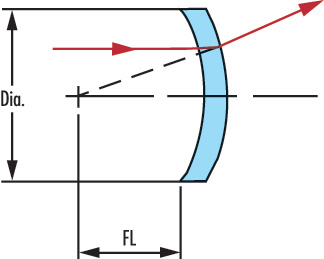

Meniscus cylinder Lens can increase the NA of the system while only adding slightly to the total spherical aberrations. The Negative Meniscus cylinder Lens is used to increase the focal length of another Cylindrical Lens while maintaining the angular resolution of the optical assembly. This lens shape is best used when one conjugate is relatively far from the cylindrical lens.

Some styles of cylindrical lenses have antireflective coatings to increase the transmission of light through the lens.

Fused silica cylinder lenses are ideal for demanding laser machining and medical applications.

Negative Meniscus cylinder lens   Â

Â

Â

Positive Meniscus cylinder Lens

Â

Specification of our meniscus cylinder lens or Plano-Convex Cylindrical Lens as follow:

*Material: BK7,Ge,UV-grade fuse silica(JGS1,JGS2,JGS3)or other optical materials

*Dimension Tolerance: +0.0 -- -0.1mm

*Center Thickness: +/-0.1mm

*Focal Length Tolerance: +/-1%

*Surface Quality:20/10

*Surface Figure: lambda/2 at 633nm on plano side

*Clear Aperture>90%

*Chamfer: 0.25mm at 45 degree typical

*Coating Optional

Meniscus Cylinder Lens,Optical Glass Meniscus Cylinder Lens,Meniscus Spheric Lens,Meniscus Cylindrical Lens

China Star Optics Technology Co.,Ltd. , https://www.csoptlens.com