In January and February 2013, the mahogany furniture market was sluggish, with slow development and limited growth. However, by March, the industry began to show signs of life, driven by a major exhibition that boosted market interest and brought renewed energy to the sector. Companies were cautiously optimistic, watching for clearer signals of recovery. Then came April—what would this month bring for the mahogany furniture industry? Was it a sign of gradual warming up?

April is a time when nature comes back to life, symbolizing renewal and growth. In English, "April" means "to open"—perhaps this reflects the beginning of a new chapter for the mahogany furniture industry. Could it be that the industry is finally starting to recover, just like the earth coming back to life after winter?

Recently, reporters visited several redwood furniture enterprises in Shenzhen, Jiangmen Xinhui, Zhongshan Dayong, and Shaxi. They found that many business leaders were very active—traveling frequently, inspecting raw materials, attending exhibitions, or exploring new markets. Some entrepreneurs who stayed behind were busy working in the factories, focusing on improving their company’s overall competitiveness.

"A lot has been going on lately," said a manager from a mahogany furniture company. "We’ve had to handle many things in the factory, and the market has been relatively good at the start of the year." This suggests that the industry might be quietly blooming again, and companies are beginning to feel the positive shift.

In fact, the busyness started as early as March, with many companies working hard to rebrand, improve operations, and prepare for the "exhibition month." But April brought even more activity—companies were not only following up on the exhibition momentum but also traveling across the country to find new distribution channels and expand their reach.

From late 2011 to early 2012, the market was cold, causing some mahogany furniture companies to worry about the future. Many believed the first half of 2012 would be tough, while some experts predicted a recovery in the second half. Industry insiders remained hopeful, pointing out that China's mahogany furniture market still had great long-term potential.

According to the current level of activity, the vice chairman of the Collection and Appraisal Committee of the Chinese Cultural Heritage Society, an expert from the same society, and the former director of the Palace Museum’s Cultural Protection Technology Department, made a notable statement during an interview at the New Product Appreciation Conference of Redwood Furniture on March 16: “The spring of the mahogany furniture industry has truly arrived.â€

It seems that the winter of the redwood market may have passed, and as temperatures rise, so does the industry’s activity. I believe the mahogany furniture market will soon regain its former glory and continue on a positive path forward. (Source: Elin Tian Tian, China Classical Furniture Net)

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Yokelink has been supplying fasteners for the wind energy industry for over 10 years. These fasteners are utilised in producing a gearbox, a valuable wind mill turbine component located within the nacelle. we also offer standard wind power energy fasteners in line with ISO or DIN, including vibration-resistant security products. Wind tower bolt plays a important role as joining components in fastening different parts of wind turbine tower, Yokelink is a professional manufacturer which supplies high grades fasteners 8.8-12.9 for wind tower projects.

Product Ranges:

We currently service all aspects of the wind turbine market, Our extensive range allows wind

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

turbine manufacturers to 'single source'all their fastener requirements with all the advantages that this brings, providing a range of fasteners, both standard and customer bespoke for:

â—Foundation

â—Tower Construction

â—Blade to Hub

â—Nacelles

â—Off-shore Transition Pieces

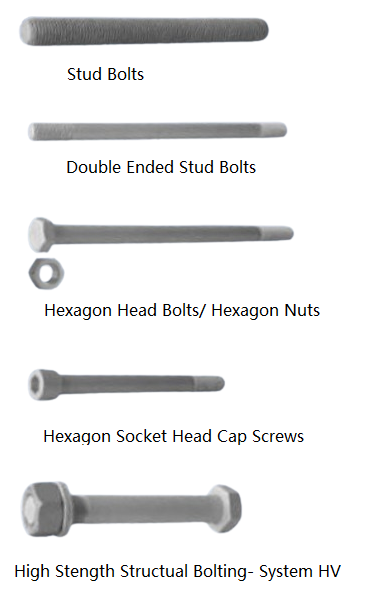

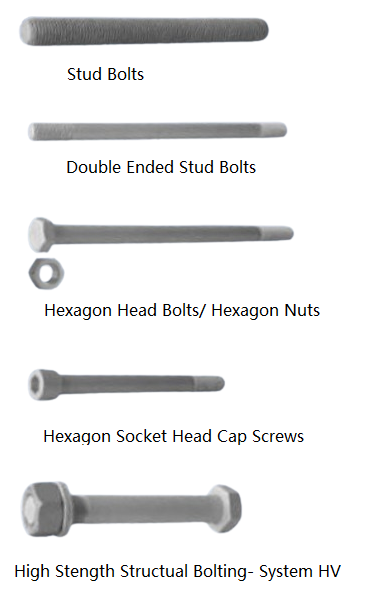

Hex cap screws DIN 931, DIN 933 and ISO 4017

Hex Bolts and Nuts, size M10-M64

Stud Bolts size M12-M64

Threaded Rods size M10-M64

Tower Flange Bolts size M10-M64

WHAT ARE WINDMILL POWER FASTENERS?

WHAT ARE WINDMILL POWER FASTENERS?

Fasteners used in wind power tower and blade connection and transmission, including hex bolts, stud bolts, tower flange bolts, foundation bolts, threaded rods, high strength double head screw, hardened and structural bolts, nuts, washers and threaded rods, and hex cap screws etc.

WHAT'S THE CHARACTERISTICS OF WIND POWER FASTENERS

High strength, high grade and precision, can work in hard conditions like extremely hot and cold environment and corrosion resisted .In wind turbine generator system, because of the randomness of power source, hardness of operating circumstances, special producing and installing, as well as high costs of maintaining, the requirements for wind turbine bolts would be extremely high. We have to take effective actions to ensure the reliability of the bolts connection, from the bolts structure design, manufacture process to production and assembling.

WHAT BOLTS ARE USED IN A WIND TURBINE?

Wind turbine bolts, there are wind turbine blade bolts, wind turbine anchor bolts, wind turbine foundation bolts, high strength and high tension hexagon head bolts, nuts and washers are mainly used for wind turbine.

HOW MANY BOLTS ARE IN A WIND TURBINE?

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

A most common 3 blades wind turbine requires almost 25,000pcs fasteners. With the rapid increase of wind energy demand in the worldwide, the fasteners for wind turbine and energy increased greatly as well. Most high strength bolts used for wind turbine are grade 10.8, grade 12.9 and the coatings are also very crucial, Dacromet are most commonly coating in wind turbine fasteners.

When you need Wind Power Fasteners, refer to above our catalog. We offer them in a full selection of sizes, provide the diameter or part number to get a quote of wind power fasteners, leave your message, or send us an email. You can also call us to get answers to your questions and place your order.

Wind Energy Fasteners Supplier China, Yokelink

sales@yokelink.com

Wind mill ,Wind Power fasteners, Wind mill Turbine, Stud Bolt, windmill energy, house wind turbine, Wind Turbine Blades

Ningbo Yokelink Machinery Co.,Limited , https://www.yokelink.com