By the second half of the 19th century, mechanical engineering had evolved into a distinct academic discipline. Throughout the 20th century, as technological advancements and the expansion of overall knowledge accelerated, mechanical engineering gradually split into more specialized fields. This process of specialization reached its peak in the mid-20th century, especially after World War II. As the volume of knowledge in mechanical engineering grew far beyond what any single individual could master, specialization became necessary. However, excessive specialization led to fragmented knowledge and limited perspectives. It became increasingly difficult to manage and coordinate large-scale projects or maintain a broad understanding of the entire system. This narrow focus also restricted technical collaboration, slowed the development of new technologies, and hindered overall technological progress. Moreover, it reduced the ability to adapt to external changes—such as the emergence of new materials, products, or shifts in supply and pricing. Experts confined to highly specialized areas often lacked the broader knowledge needed to address complex problems and faced challenges when working in teams, which made continuous learning more difficult. As a result, from the middle to late 20th century, mechanical engineering began to move toward a more integrated and interdisciplinary approach. There was a renewed emphasis on fundamental theories, a broader professional scope, and greater integration across different fields.

Jiangsu XC Intelligent Technology Co., Ltd. is a pioneer in the field of industrial segmentation, a comprehensive solution provider that integrates software and hardware development, industrial digital intelligence, and industrial cost reduction and efficiency improvement.Intelligent tool cabinet, Intelligent Material Cabinet, intelligent tool cabinet, intelligent shelf, intelligent Stereoscopic warehouse, AGV intelligent forklift, AGV intelligent handling robot, MES system development, ERP system development, SaaS system development, etc.

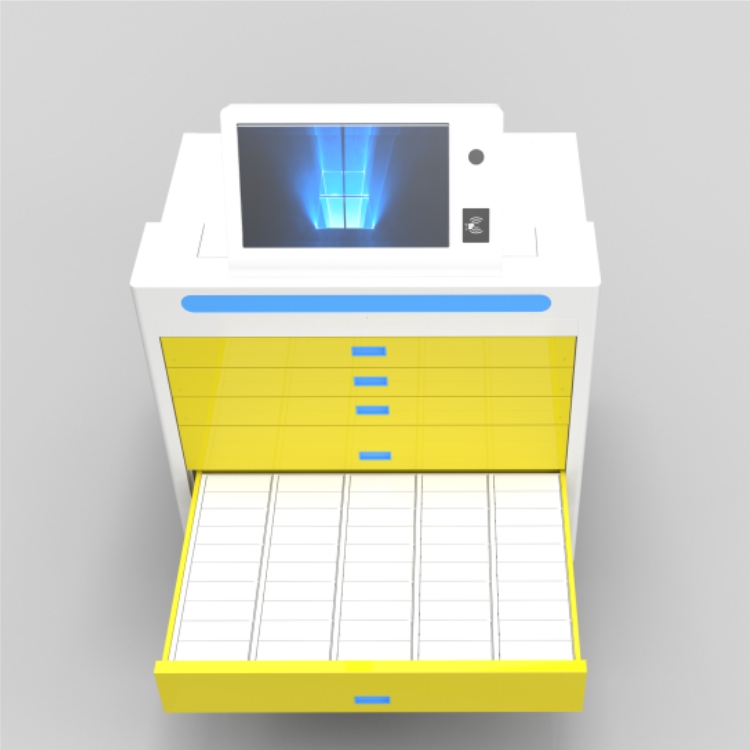

Widely used in the automotive industry, mold manufacturing, engineering machinery, power generation equipment, precision machinery High end manufacturing sectors such as aerospace and healthcare.Product weight: 250KG

Dimension: 1050mm long; 502mm thick; 1600mm high

Grid size: 135mm long; 58mm wide; 50mm high

Screen size: 21.5-inch touch screen

Product color: White yellow (customizable)

Capacity: 462 grids

Freight lane type: 11 floors * 6 lanes * 7 grids

Applicable system: optional card swiping, facial recognition, and fingerprint recognition

Power supply: AC220V/50HZ

Intelligent smart cabinet,Drawer Tool Cabinet,Drawer Storage Cabinet,Drawer Tool Storage Cabinet

Jiangsu Xicang Intelligent Technology Co., Ltd. , https://www.xciwarehousing.com